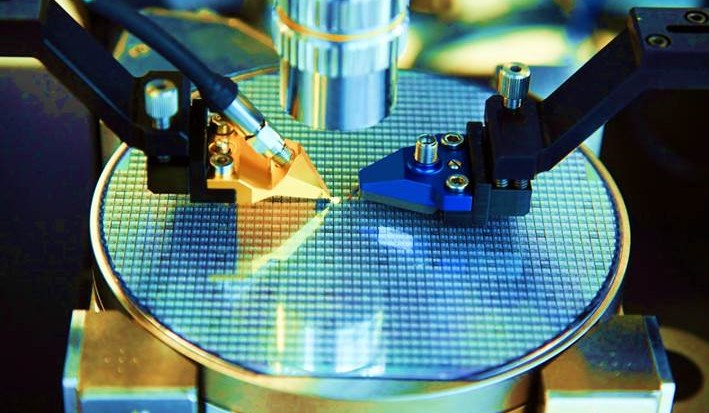

The generation of semiconductors is a complex process that involves multiple types of steps and requires stringent quality control measures to make sure that the final product fulfils the required specifications. One of the crucial quality control measures employed in the production of semiconductors is proper testing. You can come across a good semiconductor testing company that is doing phenomenal in this field.

You know, testing is the process of evaluating the electrical properties and even functionality of a semiconductor device to make sure that it fulfils the desired performance characteristics. In this post you would get to know about the effects of testing in the production of semiconductors. Before that, have a look at some basics:

What do you mean by a Semiconductor?

A semiconductor is a simple physical substance designed to manage and even control the flow of current in electronic devices and even equipment. It either does not permit a freely flowing electric current or deters the current completely.

A semiconductor sits between a conductor and even an insulator and is commonly used in the growth or formation of electronic chips, computing components, and even diverse types of devices. It is most of the time or generally created using silicon, germanium, or even other pure elements. Semiconductors are even created by adding impurities to the element. The conductance or even inductance of the element relies on the type and intensity of the overall added impurities.

There are two basic kinds of semiconductors. An N-type semiconductor gets used when its conductance is higher, or there is even a large number of free electrons. A P-type semiconductor gets used when its inductance is higher, and there are less free types of electrons. Also, you should know that the conventional types of devices and components built by using a semiconductor encompass computer memory, diodes, integrated circuits, and transistors. For now, have a look at the effects of testing on the semiconductor production:

Enhanced Quality Control

Testing is a crucial type of quality control measure in the production of semiconductors. It allows the identification of defects and even errors that may emerge during the manufacturing process. Hence, it improves the overall quality of the final product. Through testing, manufacturers can come across or detect issues such as incomplete circuits, even defective connections, and incorrect sizing of components, among others. These defects, in case not really detected and corrected, can head to the failure of the semiconductor device and, in turn, affect the performance of the final product wherein it gets used. Of course, quality is one thing that companies don’t want to compromise with.

Overall Cost Reduction

Testing is an essential type of tool for reducing costs in the production of semiconductors. By identifying different defects early in the manufacturing process, manufacturers can easily prevent costly rework or scrap. Additionally, testing simply helps to recognize defects that may arise from the use of faulty materials that may be a significant source of cost in the overall generation of semiconductors. By identifying these defects early, manufacturers can evade the additional costs of troubleshooting and even repairing products that have already been properly shipped.

Enhanced Yield

Yield is the measure of the overall percentage of working devices produced in a production process. Testing plays a crucial role in improving yield by identifying defective devices and even eradicating them from the production process. By doing so, manufacturers can avert defective devices from moving downstream in the production process, hence avoiding the cost of additional testing, troubleshooting, and even repair.

Decreased Time-to-Market

Well, it is true that testing is an essential tool for diminishing the time-to-market of semiconductor devices. By detecting defects early in the production process, manufacturers can easily prevent delays caused by the need to rework or even scrap products. Additionally, testing can help to make sure that the final product fulfils the required specifications, thereby reducing the overall need for additional testing and even troubleshooting during the process of product development. Of course, such a reduction in time to market is definitely advantageous.

Enhanced Customer Satisfaction

Testing plays a critical type of role in improving customer satisfaction by making sure that the final. Product fulfils the desired performance characteristics. Semiconductor devices that do not really fulfil or meet the required performance specifications can result. In customer dissatisfaction and even lost sales. By making use of testing to ensure that the final product satisfies. The desired performance characteristics, manufacturers can enhance customer satisfaction and even increase sales. Of course, there would be an enhanced level of customer satisfaction for sure.

A quick look at Some Challenges in Testing Semiconductors

Despite the diverse types of perks of testing in the production of semiconductors, there are even challenges that manufacturers should definitely overcome. Even the best semiconductor company may experience it if not attentive enough.

Now, one of the main challenges in testing semiconductors is the requirement for specialized equipment and expertise. Semiconductor testing demands specialized equipment, like test sockets, probe cards, and even handlers that can be expensive to acquire and maintain. Additionally, testing demands a lot of expertise in test program development and data analysis that can be challenging for smaller manufacturers having only limited resources.

Then another challenge that is there in testing semiconductors is the requirement for effective test strategies. Of course, you know semiconductor devices can have a huge range of functional and electrical properties that should definitely be tested to ensure that they fulfil the required performance specifications. Developing effective test strategies that can effectively and efficiently test all of the required properties can be quite a complex and even challenging task. there have to be proper strategies because in their absence there would not be effectivity or productivity.

Conclusion

To sum up , testing plays a critical and essential role in the production of semiconductors. It allows the overall manufacturers to identify defects and even errors in the embedded IT solution that may occur during the manufacturing process. Hence, it improves the overall quality of the final product. Additionally, it is also true that testing helps to reduce costs by classifying defects early in the production process and enhancing yield. Testing even plays a critical role in reducing the time-to-market of semiconductor devices, boosting customer satisfaction, and even enhancing sales.

More Stories

Looking for an Electric Motorcycle Showroom in Costa Mesa, CA? Tips, Benefits, and What to Expect!

Dive Deep with the HM Digital Pocket Size TDS Meter: Your Key to Water Clarity!

The Hidden Meaning of 2131953663: A Closer Look at a Numeric Code