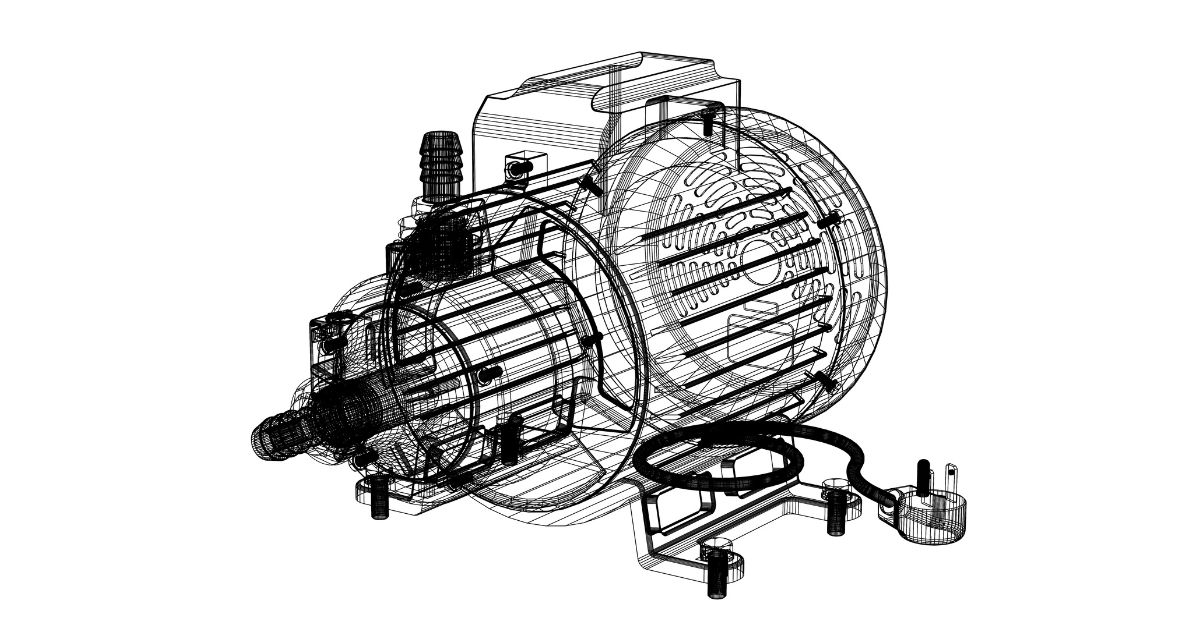

Selecting the right electric motor for a machine is a critical decision that can significantly impact your equipment’s efficiency, performance, and lifespan. With a myriad of motor types, sizes, and specifications available, it can be a daunting task to pinpoint the perfect match for your machinery’s needs. This guide simplifies the process, providing the key considerations and steps to choose the most suitable electric motor. Furthermore, leveraging a machine shop for electric motors can offer customized solutions and professional guidance to ensure your machinery operates at its peak.

Understand Your Machinery’s Requirements

Before diving into the vast sea of electric motors, it’s essential to have a clear understanding of your machine’s requirements. This includes the power needed to perform its tasks, the speed at which it operates, and the environment in which it will be used. Knowing these specifications will help narrow down your options and focus your search on motors that can meet the demands of your application.

Power and Speed

The power output of the motor, measured in horsepower (HP) or kilowatts (kW), should align with the power requirements of your machinery. Similarly, the motor’s speed, expressed in revolutions per minute (RPM), must match or adapt to your machine’s operational speed. These two factors are paramount in ensuring your machine performs efficiently and effectively.

Operating Environment

The environment in which the motor will operate also plays a crucial role in your selection process. Motors are designed to withstand different conditions, such as high temperatures, corrosive substances, or explosive atmospheres. Ensure the motor you choose is suitable for the environmental conditions it will face to avoid premature failure or safety hazards.

Consider the Type of Electric Motor

Electric motors come in various types, each with its unique characteristics and applications. Understanding the differences between AC (Alternating Current) and DC (Direct Current) motors, as well as the subtypes within these categories, is crucial. AC motors are commonly used for industrial and high-power applications, while DC motors are preferred for applications requiring variable speed control.

Consult with a Machine Shop for Electric Motors

Consulting with a machine shop for electric motors can provide valuable insights into the most appropriate type of motor for your machine. These experts have the experience and knowledge to recommend motors based on your specific requirements and can offer custom solutions if off-the-shelf options do not perfectly fit your needs.

Evaluate Motor Efficiency and Durability

Efficiency and durability are key factors that will impact the long-term cost and reliability of your motor. High-efficiency motors may have a higher initial cost but can lead to significant energy savings over time. Similarly, choosing a motor designed for durability and long life can reduce maintenance costs and minimize downtime.

Seek Assistance from a Machine Shop for Electric Motors

A machine shop for electric motors can assist in evaluating the efficiency and durability of different motors. Their expertise can help you understand the trade-offs between initial cost and long-term benefits, ensuring you make an informed decision that balances performance with cost-effectiveness.

Conclusion

Choosing the right electric motor for your machine requires careful consideration of your machinery’s requirements, the type of motor that best suits your needs, and the motor’s efficiency and durability. Consulting with a machine shop for electric motors can significantly simplify this process, providing expert advice and customized solutions to ensure your machinery operates optimally. By following these steps and leveraging professional expertise, you can select an electric motor that enhances your machine’s performance and contributes to its long-term success.

More Stories

What Makes Handmade Olive Oil Bar Soaps So Special? A Friendly Guide to Choosing and Gifting Artisan Soap Sets

How Home Inspectors Help You Avoid Costly Mistakes

How to Keep Your AC in Shape? A Friendly Guide to AC Maintenance in Roseville, CA