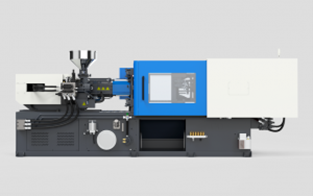

If you’re looking to increase production efficiency in your factory, we can help. Automated injection molding robots are an excellent option for companies that want to increase the speed and precision of their manufacturing process. Our automated injection molding robot technology is customizable to fit into any production environment.

Is changing production efficiency essential for you too?

Automation is one way to do it if you’re looking to improve your production efficiency. Automation means using machines or robots instead of people to perform repetitive tasks. When an automated system is designed correctly, it can be faster and more precise than humans.

Automated machines also don’t get tired or distracted like humans; they can keep working tirelessly until their task is complete–even if that takes hours or days instead of minutes! This saves money on labor costs since fewer workers are needed for each job). And because there aren’t any human errors during the process either, you’ll also end up with higher-quality products!

Are you interested in automatic injection molding robot technology?

Automatic injection molding robots are the future of manufacturing. They’re fast, accurate, and efficient and can be yours for a fraction of the cost of a traditional machine.

How much do you know about automatic injection molding robots? If you’re interested in learning more but aren’t sure where to start, here are some essential facts:

Automatic injection molding robot technology is safer than ever before. It uses sensors to monitor its environment and stop any movement if anything gets in its way. This means there’s no need for human workers on-site during operation!

It’s also fast: the average AMR cycle time is less than 10 seconds per part; this compares favorably with traditional machines. Which take several minutes or even hours per cycle depending on size/complexity (not including setup time). This means that your parts can be produced much faster than ever before–and at a lower cost per part!

What is the difference between a robot and an automatic robot?

An automatic robot is a machine that can perform tasks that would typically require human intelligence, such as efficiently moving objects and picking them up. The main difference between automatic robots and traditional robots is that. The former can be operated without any human intervention.

Automation has been around for quite some time now. Still, it wasn’t until recently that we saw an increase in their use due to technological advancements, which have made them cheaper and more accessible than ever before.

How does the automatic injection molding robot work?

An automatic injection molding robot is a machine that can do things for you. A robot is a computerized machine with sensors and motors that help it navigate and a program that tells it what to do–and, of course, a computer to run that program. The type of robot we’re talking about here can be programmed by anyone who knows how to use computers: you don’t need any special training or education in robotics or programming!

What are the advantages of an automatic injection molding robot over a conventional one?

There are many advantages to using a robot for your injection molding process. The first is that it can work 24/7. If you have an automated production line. Then the machine will run on its own without needing any human intervention. This means you can increase efficiency and reduce costs by not having to hire someone at all hours of the day or night to keep things running smoothly.

Another benefit of using an automatic injection molding robot over conventional methods is that they can much better high-temperature environments than humans can–including cold temperatures! In addition, they can also withstand higher humidity than we poor people. They will wither under such conditions if we are forced to enter them without proper protection.

Changing production efficiency is easy with our help.

Changing production efficiency is easy with our help. We have the best automation technology and are a reliable and trustworthy company, so you can trust us to care for your needs. We have a wide range of products to help you change your production efficiency, so come talk to us today!

Finally, we hope this article can help you better understand how to change productivity. If you are interested in our automated injection molding robot technology and would like more information, please get in touch with us or visit our website.

More Stories

Are High Quality Replica Watches Worth Your Time? Tips, Benefits, and More!

Understanding ASME Vessels: Key Specifications and Standards You Need to Know

Relationship Retreats vs. Traditional Therapy: Which Is Right for You?